In the competitive landscape of product manufacturing, the importance of ensuring durability and design excellence cannot be overstated. One critical tool that plays a crucial role in achieving this goal is vibration testing equipment.

Vibration testing equipment is essential for evaluating a product’s ability to withstand the rigors of transportation, use, and environmental conditions. By subjecting products to controlled vibrations, manufacturers can identify potential weaknesses and make necessary design improvements before bringing their products to market.

In this article, we will delve into how vibration testing equipment plays a pivotal role in ensuring product excellence, from enhancing durability to optimizing design features.

Importance of Durability in Product Design

The importance of durability in product design cannot be overstated, as it directly impacts the overall quality and success of a product. Durability ensures that a product can withstand the rigors of daily use, environmental factors, and potential accidents, ultimately leading to increased customer satisfaction and loyalty.

Additionally, a durable product reduces the need for frequent repairs or replacements, resulting in cost savings for both the manufacturer and the consumer. By prioritizing durability in product design, companies can enhance their brand reputation and establish themselves as leaders in the industry.

Role of Vibration Testing Equipment in Product Excellence

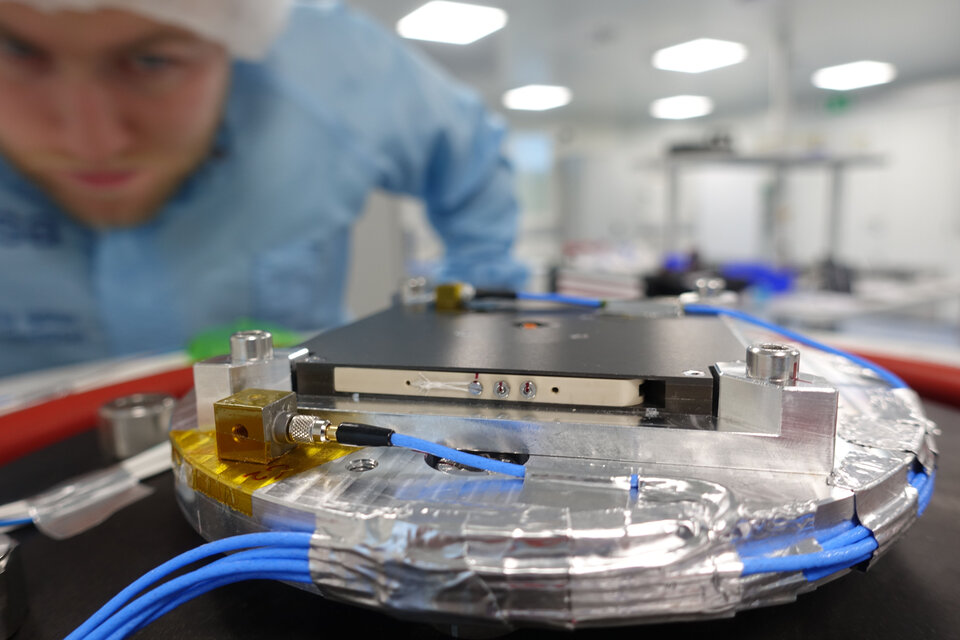

The role of vibration testing equipment in ensuring product excellence cannot be understated. By subjecting products to varying levels of vibration, manufacturers can simulate real-world conditions and identify potential weak points in their designs.

This proactive approach allows for adjustments to be made before products reach the hands of consumers, ultimately reducing the likelihood of costly recalls or warranty claims. Additionally, vibration testing equipment plays a crucial role in improving the overall durability and reliability of products, leading to increased customer satisfaction and brand loyalty. In today’s competitive market, where quality and performance are paramount, investing in vibration testing equipment is essential for any company looking to deliver excellence in their products.

Benefits of Using Vibration Testing Equipment

Using vibration testing equipment offers a wide range of benefits that can significantly enhance product quality and reliability. One of the key advantages of utilizing this equipment is the ability to identify potential design flaws or weak points in a product before it goes to market.

By subjecting products to simulated vibrations and stress testing, manufacturers can ensure that their products can withstand real-world conditions and prevent costly recalls or warranty claims. Additionally, vibration testing equipment can help optimize product performance by fine-tuning components or materials to improve durability and efficiency.

Overall, incorporating vibration testing into the product development process results in higher-quality products that meet or exceed customer expectations.

Case Studies Demonstrating the Importance of Vibration Testing

Several case studies have illustrated the significant impact of vibration testing on product reliability and performance. For example, a leading automotive manufacturer implemented vibration testing equipment during the design process of its latest vehicle model.

By subjecting the car components to various vibration frequencies, engineers were able to identify weak points and make necessary improvements to enhance the vehicle’s overall durability. In another case, a consumer electronics company conducted vibration testing on its latest smartphone to ensure that it could withstand daily wear and tear.

The results of the testing revealed potential issues with the device’s internal components, prompting the company to make design modifications before mass production. These real-world examples highlight the crucial role of vibration testing in guaranteeing product excellence and customer satisfaction.

Conclusion

In conclusion, the utilization of vibration testing equipment plays a crucial role in ensuring product excellence from durability to design. By subjecting products to rigorous testing procedures, manufacturers can identify potential weaknesses and make necessary improvements to enhance the overall quality and performance of their products.

This proactive approach not only helps in meeting industry standards but also increases customer satisfaction by delivering reliable and durable products. With the advancements in technology and the availability of sophisticated vibration testing equipment, companies can continue to innovate and push the boundaries of product design in pursuit of excellence.